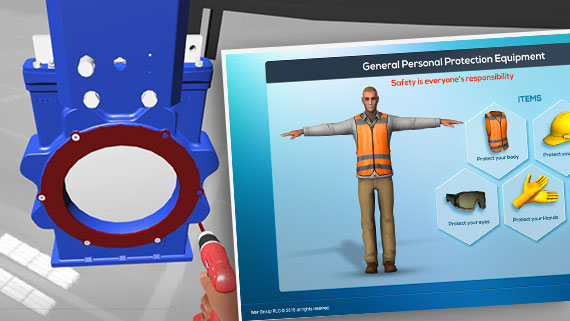

Heavy industries entail various industries like steel, manufacturing, oil and gas, mining, construction and more. AR & VR can be used in these industries to greatly aid in normal day to day operations. AR can detect the malfunction from large machinery to small bolts. AR can scan machinery parts and store the information in the cloud. Machins can be examined by a single technical expert, instead of multiple personnel if we use AR. VR can be used to simulate various hazards scenarios of the industries like the methane gas leaks and the way to handle it. AR can be used on creating the 3D virtual model of manufacturing units and these holograms can be used by engineers to interact with experts regarding installation and maintenance. VR based manufacturing simulation can duplicate the entire manufacturing process and each participant trainee gets his own virtual factory to work and learn.

To support visual guidance on the use of drilling machine which can enhance both efficiency and accuracy. We can simulate the critical situations of the industries for the employees to train how better they can deal with the situation if it ever occurs. We have realized the potential and importance of the VR in heavy industry. We are happy to say that we worked with some of the best companies in the heavy industry. Few of the app details mentioned below, we worked.